Failure Analysis of nickel superalloy components

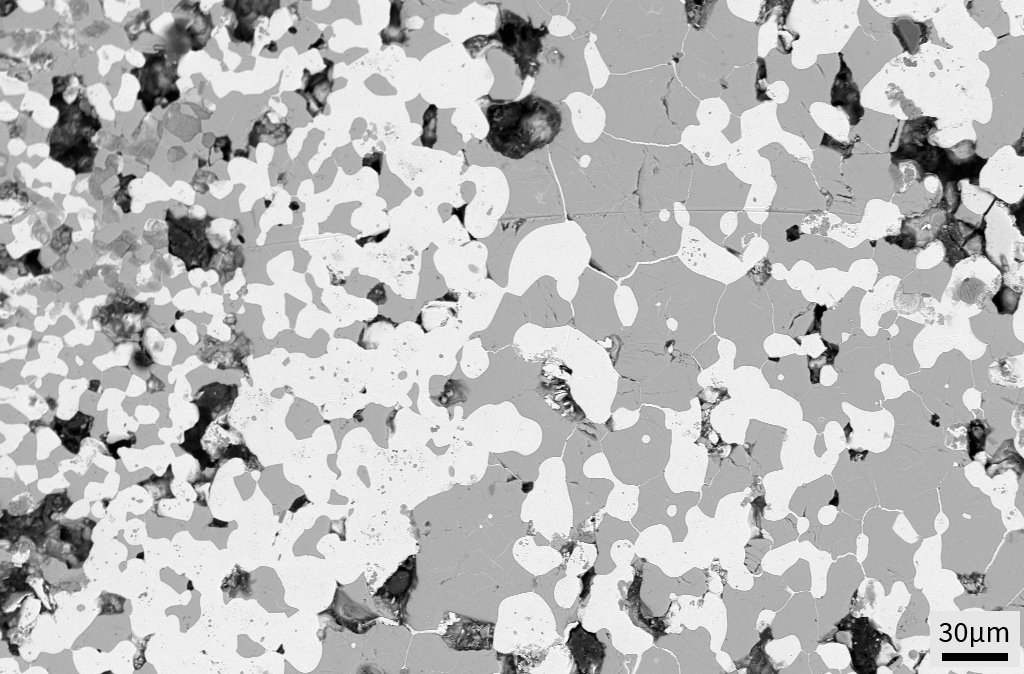

This component was caught up in a cascade failure at high temperatures, causing separation of the alloy and re-crystallisation. Failure analysis using scanning electron microscopy clearly reveals the thermal gradient across the sample, with smaller grains on the left indicating higher temperatures. By using the back-scattered electron detector, the contrast in the image is sensitive to the atomic number of the sample. On the right we can see nickel nucleating at grain boundaries, showing as bright cracks between the darker molybdenum/chromium grains.

Using Energy Dispersive X-ray spectroscopy (EDX), we can see the separation of the elements in the sample. The map matches the SEM picture, confirming the distribution of each element. Quantitative analysis can determine the proportion of each element in the sample to evaluate the composition of the alloy. Further image analysis can also measure the spatial distribution of each phase.